This article aims to define noise in an echosounder, differentiate the origins of noise, and propose steps to mitigate or attenuate it. Finally, we will discuss tools to handle unwanted information on the screen.

This is part one of a series of articles produced to unify concepts and improve the fishing captain’s experience.

An echosounder is a highly sensitive acoustic instrument. It emits pulses of ultrasound that travel through the water and bounce off various objects, producing echoes. These echoes are then received and processed to create images on the screen. The echosounder is designed to detect very low-intensity echoes.

However, during this process, various physical phenomena can cause unwanted effects on the displayed information. The screen can become “cluttered” with noise or unwanted information.

For this article, we will refer to any physical event that produces an unwanted acoustic consequence as noise. Noise can not only add unwanted information but also alter the detected echoes, leading to errors in the interpretation or measurement of the echoes.

A) Sources of Noise:

Noise can originate from a variety of sources:

1. Natural Causes:

– Rainfall: often leads to bubbling near the surface.

– Volcanic or seismic events: Can generate sound waves underwater, which may be detected by the transducer if they are within its operating frequency range.

– Waves: Cause turbulence and the formation of air bubbles.

– Animals: Emit acoustic waves, for example, cetaceans, which can interfere with the equipment.

– Algae and plankton: High concentrations can interfere with the display of desired echoes, usually from fish, on the screen.

– Ice: When ice breaks or collides with the vessel’s hull, it generates detectable sound waves.

2. Vessel-related noise (either from your vessel or a nearby vessel):

– Vibration noise: This can be caused by the propeller turning, engine activity, or the shaft line, which transmits sound waves to the water through the hull. These sound waves are then picked up by the echosounder transducer.

– Flow or displacement noise: This type of noise is caused by the flow of water displacing the vessel’s hull, leading to the formation of air bubbles that can disrupt the transmission of sound, resulting in interruptions in the image.

– Electrical noise: This type of noise is caused by electromagnetic waves emitted from various electrical devices on board. While vibration or flow noise enters the equipment as sound waves picked up by the transducer, electrical noise is induced on the cables (transducer, power supply, network, etc.) or directly on the equipment. Noises generated by battery chargers, converters, LED lights, or various electric motors are common. Electrical noise can also be self-generated by the echosounder itself, as the equipment’s electronics, due to thermal changes in the components, can produce noise that is directly induced in the receiver.

> Interference from other acoustic instruments:

The transmission of other acoustic elements may cause interference to the echo reception of our echosounder. These interferences can be caused by equipment such as:

o Other echosounders

o Sonars

o Acoustic Doppler Current Profilers (ADCP)

o Doppler logs

B) The solution to the noise problem:

When an echosounder displays noise on the screen, users often attempt to suppress it using the gain control, clutter (color suppression tool), or the various intelligent post-processing filters available in modern equipment. While this process can remove or reduce the noise, it also reduces the likelihood of detecting echoes that are at the same level as the suppressed noise. If the noise is at a very low level and does not significantly affect the normal use of the equipment, it may be acceptable to suppress or filter it. However, in some cases, simply suppressing the noise is not sufficient, and it becomes necessary to address the underlying causes of the noise.

The causes or sources of noise on an echosounder are often multiple and diverse, as discussed earlier in this article. Whenever possible, the best strategy for dealing with noise is to address its multiple causes rather than just its consequences.

To solve noise problems, we recommend following this checklist:

1) Check that the equipment is installed according to the manufacturer’s specifications, including: For example:

a. Proper positioning of the transducer in the hull.

b. Routing the transducer cable through a separate conduit and insulating it from electrical cables, while keeping the cable shielding intact.

c. Ensuring the correct grounding connections.

d. Selecting the right power supply for the equipment.

e. Locating the transmitter/receiver unit away from electrical components.

f. Ideally, synchronizing the installed equipment with other acoustic instruments on board to eliminate potential interferences.

2) If the installation is incorrect, the first step should be to modify it to eliminate as many noise sources as possible.

3) If the installation is correct and the noise continues, a thorough search should be conducted to find the source of the noise. One possible strategy is to perform a complete blackout of the ship, if possible while out of port and away from other ships, and in a completely stationary condition. Then, start switching on the various devices and machines on board one by one. This approach makes it possible to identify many of the most common sources of electrical noise and vibration.

4) If the noise is suspected to be displacement noise, it is helpful to conduct a navigation test at different speeds and causing displacement without propulsion. It may be necessary to carry out this test at different levels of vessel loading, as this may alter the hull displacement.

5) Once the cause of the noise has been identified and successfully eliminated, the problem is solved for the time being. However, due to various factors, the cause of the noise, even if identified, may be difficult or impossible to solve. In such cases, it is advisable to make use of the available tools of the echosounder to mitigate or avoid the noise.

C) Strategies for dealing with noise:

Echosounders have several tools to deal with unwanted information on the screen.

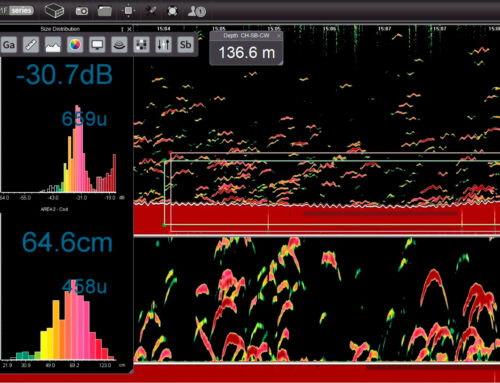

1. Gain control: By using this control, the user can determine the level of echo intensity they want to see on the screen, effectively eliminating very low-intensity echoes that are considered noise or unwanted elements. When adjusting the gain, it is recommended to start from the saturation point and then decrease it until a clear picture is achieved. However, reducing the gain may also decrease the size of the desired echoes on the screen.

2. Clutter control or color suppression: In addition to adjusting the gain level, the user has the option to suppress specific colors on the screen. Each color represents a level of intensity. By suppressing colors associated with undesired low-intensity echoes, the user can focus on relevant colors for their experience.

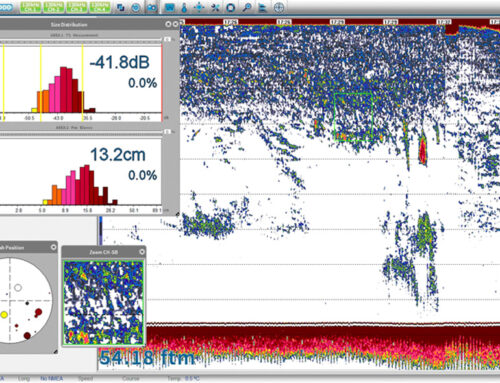

3. Interference and noise filters: When noise intensity reaches levels comparable to desired echoes, more advanced strategies need to be employed. Post-processing filters are based on models of noise behavior.

4. Adjusting the working frequency range: If filters are unable to remove the noise, an alternative strategy is to select a working frequency or frequency band that is not affected by onboard noise. The Seaman FMF echosounder is equipped with a noise detection tool to identify the affected frequency, enabling the operator to choose a different range. This requires the echosounder to be fitted with a transducer.

In this first part, we extensively explored the challenge of identifying noise on echosounders used in professional fisheries and detailed strategies for improving visualization. In a future installment, we will discuss noise in FM pulse or CHIRP echosounders, providing more tools to improve the accuracy and efficiency of the equipment.

This article aims to define noise in an echosounder, differentiate the origins of noise, and propose steps to mitigate or attenuate it. Finally, we will discuss tools to handle unwanted information on the screen.

This is part one of a series of articles produced to unify concepts and improve the fishing captain’s experience.

An echosounder is a highly sensitive acoustic instrument. It emits pulses of ultrasound that travel through the water and bounce off various objects, producing echoes. These echoes are then received and processed to create images on the screen. The echosounder is designed to detect very low-intensity echoes.

However, during this process, various physical phenomena can cause unwanted effects on the displayed information. The screen can become “cluttered” with noise or unwanted information.

For this article, we will refer to any physical event that produces an unwanted acoustic consequence as noise. Noise can not only add unwanted information but also alter the detected echoes, leading to errors in the interpretation or measurement of the echoes.

A) Sources of Noise:

Noise can originate from a variety of sources:

1. Natural Causes:

– Rainfall: often leads to bubbling near the surface.

– Volcanic or seismic events: Can generate sound waves underwater, which may be detected by the transducer if they are within its operating frequency range.

– Waves: Cause turbulence and the formation of air bubbles.

– Animals: Emit acoustic waves, for example, cetaceans, which can interfere with the equipment.

– Algae and plankton: High concentrations can interfere with the display of desired echoes, usually from fish, on the screen.

– Ice: When ice breaks or collides with the vessel’s hull, it generates detectable sound waves.

2. Vessel-related noise (either from your vessel or a nearby vessel):

– Vibration noise: This can be caused by the propeller turning, engine activity, or the shaft line, which transmits sound waves to the water through the hull. These sound waves are then picked up by the echosounder transducer.

– Flow or displacement noise: This type of noise is caused by the flow of water displacing the vessel’s hull, leading to the formation of air bubbles that can disrupt the transmission of sound, resulting in interruptions in the image.

– Electrical noise: This type of noise is caused by electromagnetic waves emitted from various electrical devices on board. While vibration or flow noise enters the equipment as sound waves picked up by the transducer, electrical noise is induced on the cables (transducer, power supply, network, etc.) or directly on the equipment. Noises generated by battery chargers, converters, LED lights, or various electric motors are common. Electrical noise can also be self-generated by the echosounder itself, as the equipment’s electronics, due to thermal changes in the components, can produce noise that is directly induced in the receiver.

> Interference from other acoustic instruments:

The transmission of other acoustic elements may cause interference to the echo reception of our echosounder. These interferences can be caused by equipment such as:

o Other echosounders

o Sonars

o Acoustic Doppler Current Profilers (ADCP)

o Doppler logs

B) The solution to the noise problem:

When an echosounder displays noise on the screen, users often attempt to suppress it using the gain control, clutter (color suppression tool), or the various intelligent post-processing filters available in modern equipment. While this process can remove or reduce the noise, it also reduces the likelihood of detecting echoes that are at the same level as the suppressed noise. If the noise is at a very low level and does not significantly affect the normal use of the equipment, it may be acceptable to suppress or filter it. However, in some cases, simply suppressing the noise is not sufficient, and it becomes necessary to address the underlying causes of the noise.

The causes or sources of noise on an echosounder are often multiple and diverse, as discussed earlier in this article. Whenever possible, the best strategy for dealing with noise is to address its multiple causes rather than just its consequences.

To solve noise problems, we recommend following this checklist:

1) Check that the equipment is installed according to the manufacturer’s specifications, including: For example:

a. Proper positioning of the transducer in the hull.

b. Routing the transducer cable through a separate conduit and insulating it from electrical cables, while keeping the cable shielding intact.

c. Ensuring the correct grounding connections.

d. Selecting the right power supply for the equipment.

e. Locating the transmitter/receiver unit away from electrical components.

f. Ideally, synchronizing the installed equipment with other acoustic instruments on board to eliminate potential interferences.

2) If the installation is incorrect, the first step should be to modify it to eliminate as many noise sources as possible.

3) If the installation is correct and the noise continues, a thorough search should be conducted to find the source of the noise. One possible strategy is to perform a complete blackout of the ship, if possible while out of port and away from other ships, and in a completely stationary condition. Then, start switching on the various devices and machines on board one by one. This approach makes it possible to identify many of the most common sources of electrical noise and vibration.

4) If the noise is suspected to be displacement noise, it is helpful to conduct a navigation test at different speeds and causing displacement without propulsion. It may be necessary to carry out this test at different levels of vessel loading, as this may alter the hull displacement.

5) Once the cause of the noise has been identified and successfully eliminated, the problem is solved for the time being. However, due to various factors, the cause of the noise, even if identified, may be difficult or impossible to solve. In such cases, it is advisable to make use of the available tools of the echosounder to mitigate or avoid the noise.

C) Strategies for dealing with noise:

Echosounders have several tools to deal with unwanted information on the screen.

1. Gain control: By using this control, the user can determine the level of echo intensity they want to see on the screen, effectively eliminating very low-intensity echoes that are considered noise or unwanted elements. When adjusting the gain, it is recommended to start from the saturation point and then decrease it until a clear picture is achieved. However, reducing the gain may also decrease the size of the desired echoes on the screen.

2. Clutter control or color suppression: In addition to adjusting the gain level, the user has the option to suppress specific colors on the screen. Each color represents a level of intensity. By suppressing colors associated with undesired low-intensity echoes, the user can focus on relevant colors for their experience.

3. Interference and noise filters: When noise intensity reaches levels comparable to desired echoes, more advanced strategies need to be employed. Post-processing filters are based on models of noise behavior.

4. Adjusting the working frequency range: If filters are unable to remove the noise, an alternative strategy is to select a working frequency or frequency band that is not affected by onboard noise. The Seaman FMF echosounder is equipped with a noise detection tool to identify the affected frequency, enabling the operator to choose a different range. This requires the echosounder to be fitted with a transducer.

In this first part, we extensively explored the challenge of identifying noise on echosounders used in professional fisheries and detailed strategies for improving visualization. In a future installment, we will discuss noise in FM pulse or CHIRP echosounders, providing more tools to improve the accuracy and efficiency of the equipment.